Sanitary Design

A solid food safety system depends on many elements, such as HACCP plans and Sanitation Standard Operation procedures. However, these elements cannot stand on their own merit without a facility designed to facilitate the implementation of these plans. Facility planning and design is part of the foundation on which a good food safety system is built.

Facility design to incorporate food safety starts with the following key elements:

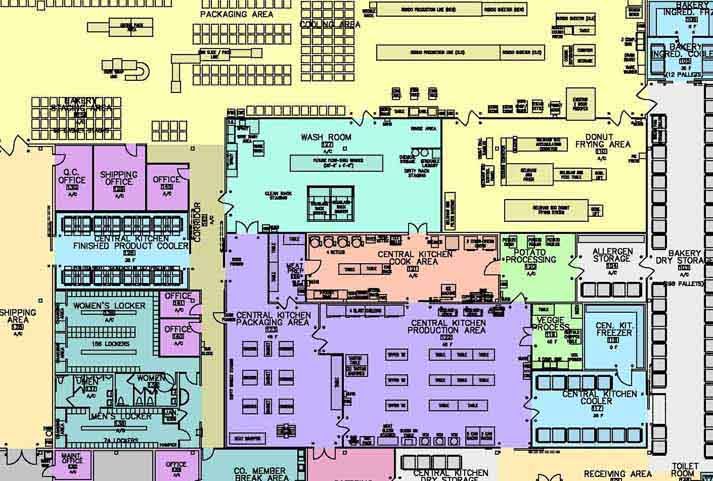

The first key element involves the layout and planning of a facility: A proper layout will minimize the potential for the creation and proliferation of food safety hazards.

The second key element involves the design of the materials and components in a food facility: A proper design will enhance the ability to maintain sanitary conditions.

The following is a list of the top facility design elements which must be controlled in order to achieve and maintain a sanitary facility:

Hygienic Zones Control

Maintain physical separations that reduce the likelihood of the transfer of hazards from one area or process of the facility to another area or process.

Flow Control

Establish traffic and process flow that control movement of production workers, managers, visitors, QA staff, sanitation and maintenance personnel, products, ingredients, rework, and packaging materials to reduce food safety risks.

Water Control

Design and construct a building system (floors, walls, ceilings, and, supporting infrastructure) that prevents the development and accumulation of water. Ensure that all water positively drains from the process area and that these areas will dry during the allotted time frames.

Environmental Control

Control room temperature and humidity to facilitate control of microbial growth. Keeping process areas cold and dry will reduce the likelihood of growth of potential food- borne pathogens. Ensure that the HVAC/ refrigeration systems serving process areas will maintain specified room temperatures and control room air dew point to prevent condensation.

Air Flow Control

Design HVAC/ refrigeration systems for process areas to ensure air flow will be from more clean to less clean areas, filter air to control contaminants, provide outdoor makeup air to maintain specified airflow, minimize condensation on exposed surfaces, and capture high concentrations of heat, moisture and particulates at their source.

Spatial Control

Provide interior spatial design that enables cleaning, sanitation and maintenance of building components and processing equipment.

Sanitation Control

Provide proper sanitation systems to eliminate the chemical, physical and microbiological hazards existing in a food facility environment.

Building Components Control

Design building components to prevent harborage points, ensuring sealed joints and the absence of voids. Facilitate sanitation by using durable materials and isolating utilities with interstitial spaces (walkable ceilings) and stand offs.

Utility System Control

Design and install utility systems to prevent the introduction of food safety hazards by providing surfaces that are cleanable to a microbiological level, using appropriate construction materials, providing access for cleaning, inspection and maintenance, preventing water collection points, and preventing niches and harborage points.

Site Elements Control

Provide site elements such as exterior grounds, lighting, grading, and water management systems to facilitate sanitary conditions for the site. Control access to and from the site.

Building Envelope Control

Design and construct all openings in the building envelope (doors, louvers, fans, and utility penetrations) so that insects and rodents have no harborage around the building perimeter, easy route into the facility, or harborage inside the building. Design and construct envelope components to enable easy cleaning and inspection.